A Lesson in Failure

Jordan took great pride in the canopies and tool racks his company manufactured for utes. He had dedicated years to refining his designs, ensuring they could endure the harshest conditions, whether installed on utes bound for remote construction sites or service vehicles navigating rough terrain.

His customers swore by his products, commending their durability and craftsmanship. Yet, despite his best efforts, something was beginning to go awry.

It started with a phone call from one of his most loyal customers. The service body they’d bought six months earlier was as sturdy as ever, but the company’s logo proudly displayed on the canopy, had all but disappeared. The once-polished metal nameplate had faded to a dull, scratched-up shadow, and the critical rating information on the VIN plate had become illegible. To make matters worse, the warning labels on the tool racks, intended to provide load limits and safety instructions, were peeling off. Jordan knew he had a problem.

As the complaints started piling up, Jordan realised he had overlooked something small but crucial. He had focused so much on making his canopies and tool racks tough that he hadn’t considered the materials he was using for the badges, nameplates, and labels. What seemed like minor details were quickly becoming major liabilities.

Facing reality

Jordan's failure was a hard pill to swallow. His canopies and racks were built to withstand the daily grind; exposure to dust, grime, and Australia’s unpredictable weather. And now the badges and labels were failing in the face of these same elements. This seemingly small oversight was damaging his brand’s image and leaving his customers with products that didn’t quite feel as premium as advertised.

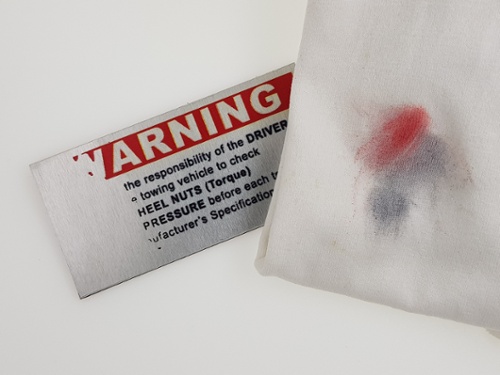

Image: product examples, before exposure and after exposure to the harsh Australian climate

It wasn’t that Jordan didn’t care about quality. It was just that he hadn’t been thoughtful enough about the details. He was learning the hard way that a tough product requires tough branding, especially when it comes to metal nameplates and labels.

What could have been different

If Jordan had done more research, he would have learned about the importance of using fully anodised metal nameplates for his canopies and tool racks. Unlike standard plates, fully anodised ones are built to resist fading, scratching, and even solvents—common threats in the environments his products lived in. By opting for this higher-quality material, the logos, serial numbers, and rating information would have stayed crisp and legible, regardless of the conditions.

For the warning labels, Jordan could have chosen top-tier materials with the right adhesives and clear top coatings for extra protection. These labels would have withstood the wear and tear of daily use, instead of peeling off after a few months. Had he made these choices from the start, Jordan would have avoided the costly and embarrassing complaints from his customers.

%201.jpg?width=3024&height=2268&name=20190822_141736%20(3)%201.jpg)

Turning failures into a badge of honour

Determined to fix the problem, Jordan used fully anodised metal nameplates for all his future canopies and tool racks. He sourced the highest quality materials for warning labels, ensuring they were coated and adhered properly to last through even the toughest conditions. He didn’t just solve the problem, he turned his failure into a learning experience, becoming an expert in this overlooked but essential detail.

Jordan now proudly tells customers that every nameplate, badge and label on his products is designed to last just as long as the canopies and racks themselves. Ensuring durability is now an important part of his overall build process and has a valuable impact.

In the end, Jordan’s failure wasn’t in making a weak product, it was in underestimating how much consideration even the smallest details require. His products were always tough, but now they’re equipped with badges and labels tough enough to match.

Contact the specialists at LNI

If you provide ute canopies, service bodies or trays and are after a badge, metal nameplate or label that is tough enough to withstand conditions your products are exposed to, then please contact LNI today.

.svg)