The Role of Calibration and Testing Labels in Australian Industries

Calibration and testing labels play a pivotal role in ensuring the accuracy, quality control, and compliance of equipment in various industries.

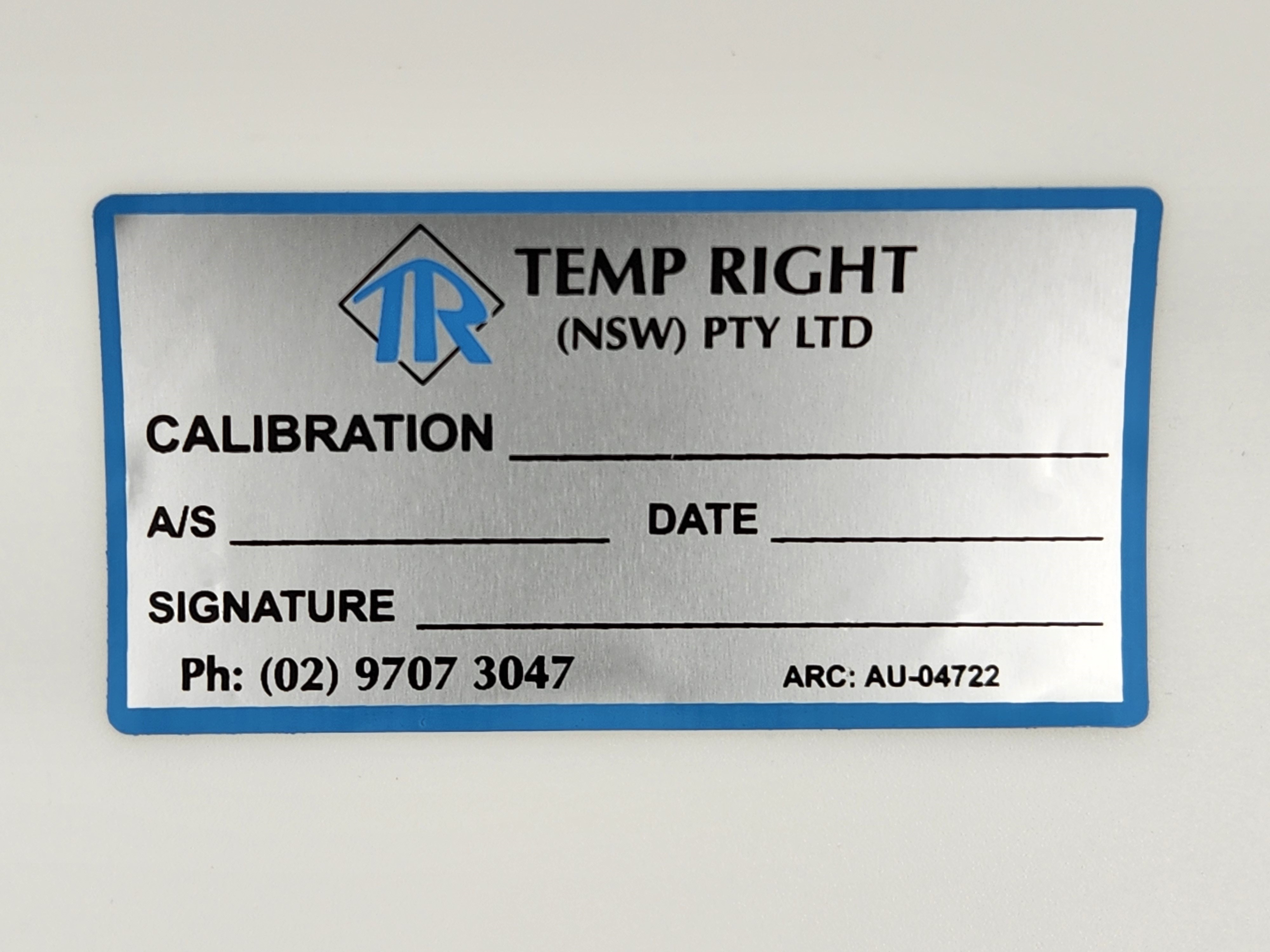

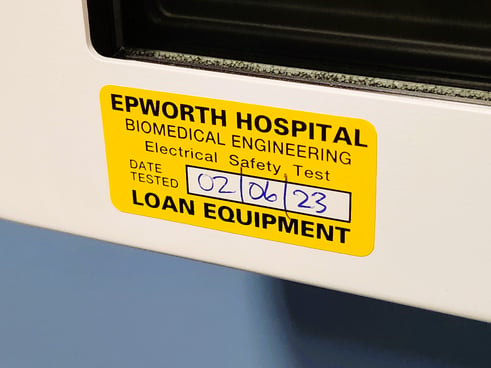

The importance of calibration and testing labels lies in their ability to maintain industry standards and safety, ensuring that equipment functions correctly and safely, thus preventing accidents and errors. The labelling can be in the form of self-adhesive labels or metal nameplates and is affixed to equipment to indicate that they have been tested and calibrated according to specific standards.

What you must know about compliance and rating labels >

Critical industries such as medical, scientific, food processing and refrigeration rely heavily on these labels for regular compliance and safety checks. For example, in the medical industry, calibration labels on diagnostic equipment such as MRI machines or blood storage refrigerators are crucial for patient safety and accurate diagnosis.

Compliance Label Solutions

The significance of calibration and testing labels extends across various sectors, each with its unique requirements for compliance and safety checks. In the scientific research field, precise measurements are fundamental, and calibration labels ensure that instruments like microscopes and centrifuges are accurate. Similarly, the food and refrigeration industries depend on these labels to verify that storage temperatures are maintained, ensuring food safety.

The pharmaceutical industry showcases the need for meticulous attention to detail when it comes to calibration. Accurate calibration of equipment used in the manufacturing of medications is vital to ensure product quality and patient safety. A simple calibration error can lead to ineffective or even harmful medication batches, underlining the importance of these labels in quality control processes.

Specialised Calibration and Testing Label Solutions

LNI stands out as a provider of tailor-made calibration labels designed to meet the stringent compliance services required across many industries. With an array of base materials available, LNI offers durable indoor and outdoor calibration and maintenance labels that cater to various environmental conditions, ensuring legibility and longevity.

LNI's custom in-house design capabilities enable the creation of industry-specific labels, ensuring that all equipment meets the required standards for durability and readability. For example, in the heavy machinery sector, LNI can produce rugged metal nameplates that withstand harsh conditions while maintaining clear inspection and calibration records.

Read more industry examples and details on the various labelling products LNI manufacturers and can design specifically for you here: What you must know about compliance and rating labels >

Partner with the specialists

Choosing a reliable and experienced label provider like LNI ensures compliance, durability, and accuracy in calibration and testing labels. With over 50 years of experience and current certification of IATF 16949, ISO 9001 and ISO 14001 quality standards, LNI's dedication to providing the best branding solutions is evident.

LNI's expertise, custom solutions, and commitment to quality make them a leader in the field. All LNI’s products are designed and manufactured here in Australia so if your business is seeking reliable calibration and testing label solutions, contact LNI for your product labelling needs.

Contact the specialists at LNI

For more information on LNI's range of products, and to discuss specific requirements, please contact us, request a quote or request a sample here.

.svg)