How LNI proves its products will last

Read or listen below to Michael Smith, National Sales Manager at LNI, where he shares insights into the significant role product testing plays in manufacturing all their labels, nameplates and badges.

For 50 years, LNI has built their reputation on durability. This encompasses crucial aspects such as retaining safety and other important information on labels, nameplates and badges.

LNI places great emphasis on ensuring that its products can withstand the harsh climate of Australia, renowned for its relentless exposure to intense UV rays. Creating branding products like labels, badges, and nameplates that can endure Australia's climate is a real challenge.

What does durable mean for product branding?

- Resistance to UV rays

- Resistance to fading

- Protection against salt spray

- Protection against humidity

- Resistance to scratching or abrasion

- Resistance to chemicals and cleaning products

This is particularly important for customers in the automotive and defence industries, who demand these specifications.

To validate the durability of their products, LNI employs two key methods

The first is outdoor exposure testing at the Allunga Outdoor Exposure Lab in Queensland.

The first is outdoor exposure testing at the Allunga Outdoor Exposure Lab in Queensland.

Products are placed there for two years, with periodic testing and reporting on their performance. This lab provides an extreme climate, including high temperatures, varying humidity levels and rainfall.

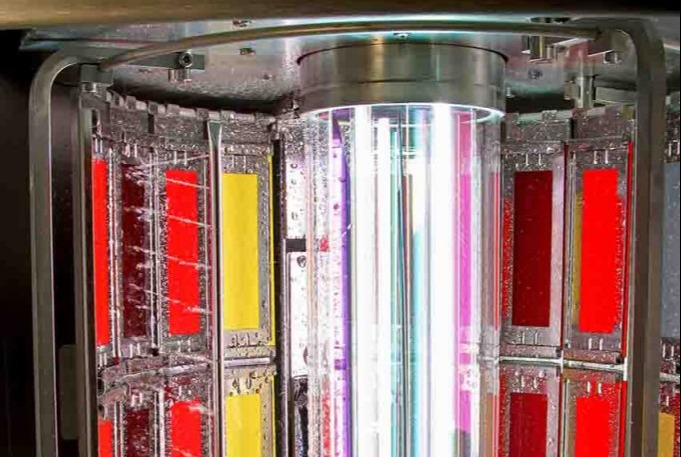

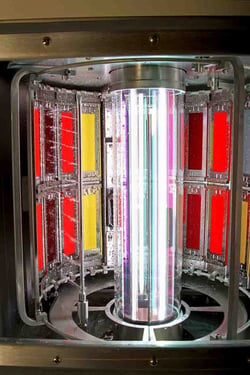

The second method is accelerated weatherability testing, which is done artificially in a xenon arc testing chamber.

This simulates two years of exposure by subjecting the products to high UV, rain, salt spray, and different humidity levels. This testing is conducted by an external lab, and periodic reports are provided over the testing time, usually over three months. Fading or colour fastness is a primary focus during this testing, along with image clarity and resistance to salt spray, humidity, high heat, and low heat.

In addition to these tests, the lab also conducts other assessments such as:

- abrasion testing

- tensile strength

- adhesive strength

- flammability testing

LNI goes through these rigorous tests to ensure that their products are fit for purpose and meet the requirements typically for automotive and defence customers.

Don't just take LNI's word for it, check out the test results below.

Not long ago, LNI completed a full two-year exposure test at Allunga in Queensland, where they tested a range of products typically sold in the market. They not only look for products that pass these tests but also include products that they know will fail within two years. Understanding when and why they fail is crucial.

LNI has long-standing customers who have been with them for 20 to 30 years since their first order. LNI takes pride in going above and beyond the efforts of its competitors to provide products that meet their needs. When LNI recommends a product, they want to be confident that it will perform as expected, backed by validated data. This commitment to customer satisfaction is the core of LNI's business.

Talk with a specialist today

Whether you are looking for Nameplates, Badges or Labels, contact the specialists at LNI today.

.svg)