Every detail counts with state of the art medical equipment: NOTUS Emergency Invasive Ventilator

LNI is proud to be a part of the production for the NOTUS Emergency Invasive Ventilator Program, a Grey Innovation led initiative supported by the Australian Government, Victorian Government and Advanced Manufacturing Growth Centre.

Coupled with an advanced level of craftsmanship for developing the control panel facia (Graphic Panel) on the medical device itself, and the warning labels for instructions and serial number labels. Medical products require a superior process for design and manufacture due to the conditions of use and need for precision. Graphic Panels require a great deal of finesse when balancing the product between its clean design, durability and usability - LNI are no strangers to creating a vast array of high-quality Graphic Panels across different industries.

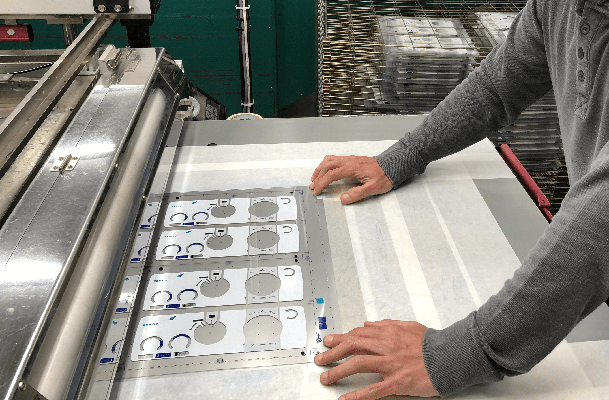

Figure 1: NOTUS Graphic Panel back printing

If you look closely at the graphic panel on the video below you will notice that each icon on the facia panel is clear. The purpose of this is to improve user experience day or night by making sure each icon is visible in reduced lighting by being lit from behind.

Figure 2: Back printing on graphic panel

Graphic Panels, or facias, are screen-printed using a technique called back-printing which uses a clear film product married with transparent and opaque strength inks (as seen in the video below).

Figure 3: Addition of polycarbonate film

The extra value in back-printing allows for the option of having different textures on the front surface of the polycarbonate film. Also, because the print is on the reverse side it means it drastically improves the lifespan of the product by reducing the ability to be scratched or damaged by cleaning agents over time.

Figure 4: Die-cutting Notus graphic panel

The second products required for the NOTUS Emergency Invasive Ventilator was the warning labels created for instructional use and serial number for the manufacturer’s product identification. Warning labels are a crucial component for all medical equipment as the message they convey can help save lives during operation. Making sure that the final product had a clear and long-lasting label meant using the correct product for the job. LNI used a particular type of clear polycarbonate film and back-printed the labels using digital print technology. Digital printing meant LNI could safely rely on the fast turnaround time for the product without sacrificing quality to the label itself.

The industrial grade digital printer seen in the video below shows just what we mean by timely and precise production, with the ability to print multiple products at a time we can rely on making the deadlines for the ventilator.

Figure 5: Digital printing Notus Warning Label

Finally, the products are cut to shape using some of LNI’s highly efficient manufacturing machinery that allows for fast and effective production ready for use.

Figure 6: Die-cutting Notus Warning Label

Creating a high-quality product for the job is easy when working with the right team, LNI was honoured to have the opportunity to work with all parties involved in the creation of the NOTUS Emergency Invasive Ventilator.

Talk with the experts

To get the best possible branding product for your next project talk to the experts at LNI. Contact us today - we can solve any tricky labelling problem you may be experiencing.

.svg)