Testing and calibration - the importance of labels

Working in the calibration, testing and quality control sector requires accuracy, fastidious attention to detail and record-keeping. Testing and tagging are particularly important in the medical, scientific, food and refrigeration industries, where compliance with regulations needs to be stringently monitored.

At LNI, we understand that once an asset has been verified for safety, accuracy and compliance, a label is usually used to record and track calibration and testing requirements, often hand-in-hand with electronic record-keeping.

These labels need to be:

- Easy to apply

- Easy to write on

- Tamper-proof

- Available in a wide range of colours and styles.

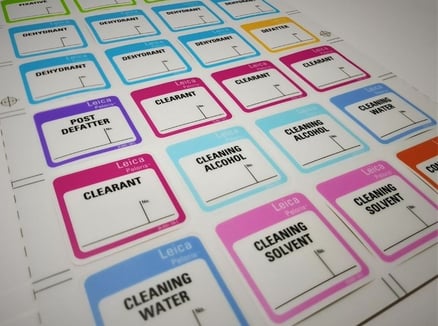

LNI has a comprehensive range of calibration tags and labels for use in measurement, testing, inspection, quality control and compliance services to ensure assets meet their required state, national and international accredited standards. Read more below for industry examples and the many varied labelling options available to suit your products.

Example - The importance of elevator inspections

Every day, millions of people around the world rely on elevators to get to and from their homes and workplaces. Regular testing and inspection of elevators is critical as the consequences of failure could be catastrophic!

One of our clients conducts annual safety inspections for elevators and lifts in buildings. These routine checks require validation, typically involving metal nameplates to document the latest information at each inspection. These elevator nameplates are essential for elevator testing and inspections. Any changes, inspections, or modifications must be documented and noted on these plates. These plates ensure that elevators remain in compliance with all applicable standards.

Example - Pharmaceuticals – accuracy is essential

Another industry where calibration and accuracy are essential is pharmaceutical. Many instruments and machines are used to measure and manufacture pharmaceutical products. Product quality and safety rely on accuracy, so strict calibration practices are critical to ensure compliance and minimise costs associated with lost batches, not to mention the potential fines for any breaches.

LNI’s durable, custom calibration and maintenance labels are used throughout major medical and pharmaceutical organisations, ensuring you meet any industrial standard requirements.

Why choose calibration and testing labels from LNI?

- LNI offers a wide range of base materials including vinyl, polyesters, clear polycarbonates, metallised films, electrostatic and foil.

- LNI’s self-adhesive labels can be engineered for full outdoor durability including resistance to UV, weather, abrasion and chemicals.

- Need a specific shape for your label? LNI can cut labels to any custom design, and have a full range of traditional shapes like squares, ovals and rectangles.

- Can’t afford to have your label fail? Some of LNI's labels are made to self-destruct if someone attempts removal, while others are permanently indented when written on with a pen, so if the pen is rubbed off, the indentation on the label can still be read (how clever is that)!

- LNI can supply labels as single parts, on sheets or in strips.

And all of LNI’s labels are designed, engineered and made right here in Australia.

Contact the specialists at LNI

If you are in the business of calibration, testing or certification and need labels or nameplates you can rely on, please get in touch with us. We take the time to get to know our customers and have a solution for any labelling or product branding need.

Contact us today, or call us on 03 9721 4200 or 02 9609 3699 to discuss the best solution for your needs.

.svg)