A metal nameplate can come in various shapes, colours, sizes and thicknesses. Read on to watch a recent Q&A video with Michael Smith, National Sales Manager at LNI, where he explains all about the key characteristics of metal nameplates.

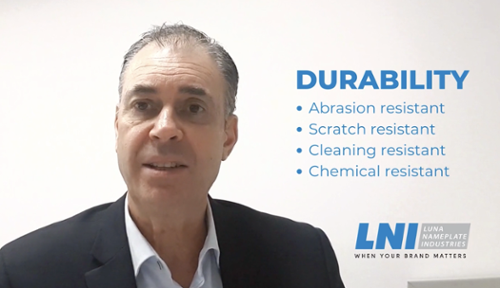

Finding the right metal nameplate for your company/product can be challenging as a level of durability and quality must be met.

One of the metals we use is aluminium, which is lightweight, durable and strong compared to other materials. The last thing you need is to have your identification, compliance, safety or rating nameplates fade or deteriorate quickly over time.

Below are some key characteristics of metal nameplates that will assist you in the decision-making process.

Etched, embossed, printed, dyed or formed

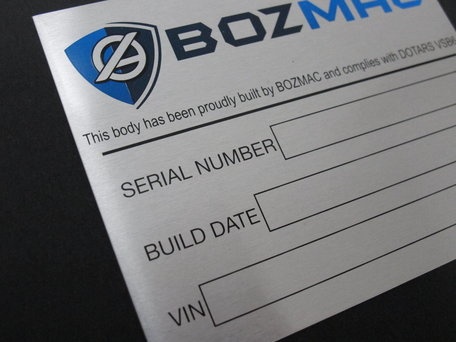

Nameplates that can be etched, embossed, printed dyed or formed will help you achieve your nameplate needs in terms of resilience, longevity, durability and overall look and feel of the nameplate. Two popular techniques of metal nameplates are etching and screen printing. Etching involves removing specific areas of the metal using a chemical process to create designs and graphics. Etched nameplates are generally used for equipment labelling, machine identification and rating labels. Perfect for automotive compliance - Luna Nameplate Industries has been tested and validated to all applicable automotive exterior and interior specifications.

Alternatively, screen printing is a cost-effective and durable solution used to achieve a decorative product. By doing so, ink is stencilled on the metal to create a desired image or design, ideal for indoor and outdoor applications with long-lasting results.

Engineered for outdoor applications using an anodising process

Metal nameplates for use in the commercial industry, such as machinery, equipment, sheds and fencing must be able to tolerate harsh or corrosive environments as opposed to use at home or in the office. Metal nameplates must be durable and resilient enough to withstand extreme temperatures, outdoor exposure, abrasion, salt spray and most chemicals. An example would be the RV & Marine industry. A specialised anodising method can ensure that nameplates will not fade or deteriorate quickly over time. Anodising is an electrolyte process in which a thick coat of oxide is added to the surface of the aluminium designed to increase corrosion resistance.

Mounting holes, adhesive or both

Given nameplates are used for a wide variety of indoor and outdoor applications, it’s important to ensure mounting holes or adhesives are supplied. Without this functionality, it makes the application more difficult. Nameplates can be applied to many surfaces such as plastic, metal, cardboard and walls and there are pros and cons for each surface. At the same time, there are many mounting and adhesive options available which vary depending on the size of your nameplate. For instance, smaller nameplates generally allow for one or two mounting holes, whereas, larger nameplates can allow up to four mounting holes in each corner.

Nameplates can be mounted to many surfaces including walls, doors, vehicles and units. Brackets and screws are the most common and easiest ways to install nameplates.

Adhesives, on the other hand, are mainly suitable for outdoor and wet applications such as plastics, metal and powder-coated materials. It is important to consider the surface condition as this will ultimately determine the bond capability. For instance, texture is one determinant. This means if applied to an uneven surface, a foam adhesive option is suitable for filling in the gaps between the two surfaces. Read more about adhesives and download our adhesives eBook here.

Other than product application, factors like environment and exposure are other elements to take into consideration. These elements require stronger adhesives to be able to withstand extreme weather exposure and harsh chemicals. The right adhesive largely depends on the surface the orientation of the nameplate combined with the conditions it is likely to experience and the longevity required.

Talk with a product branding specialist at LNI

Contact us at Luna Nameplate Industries to receive design and application solutions for your metal nameplate.